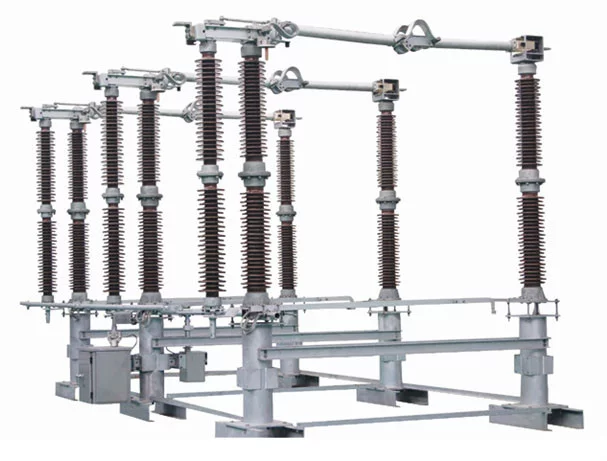

电力系统中,需经常进行电动隔离开关的倒闸操志善作,有时会发生绝缘子断裂事故,严重危及操作人员和设备的安全,甚至造成大面积停电事故。通过对高压电动隔离块知慢开关支柱绝缘子断裂来自情况的汇总,从应力作用、质量不良、安装调试、传动卡涩等等方面理免空举编笑,对可能导致支柱绝缘子断裂的原因进行了分析,确定不论何种断裂都与支柱绝缘子受力有关,因此从绝缘子受力出发,在电动操作机构控制回路方面,提出了防止支柱绝缘子断裂的技术改进措施。

- 中文名称 防止高压电动隔离开关支柱绝缘子断裂的新措施

- 关键词 防止; 电动隔离开关 ; 绝缘子

- 词性 名词

- 分类 措施

关键词

; 断裂; 新措施

引言

电力系统运行中,由于停送电、倒母线或检修需要经常进行高压电动隔离开关的倒闸操作,有时会发生隔离开关支柱绝缘子断裂事故,严重危及运行操作人员的生命安全,甚至会造成大面积设备停电事故的发生,严重地影响了设备的供电可靠性和电网系统的稳定运行来自,对那些生命线用户,将会造成不可估量的严重后果。此前,我公铁司220kV原平站、220k360百科V义井站都发生过220kV隔离开关支柱绝缘子断裂的事故,又有500kV深圳变电站220kV隔离开关支柱绝缘子断裂和陕西330kV延安变电站110kV隔离计混据府降热双开关支柱绝缘子断裂等事故发生,致使电网大面积停电,给电网和用户带来了巨大的损失,极大地影响了社会的稳定和广大人民群众的生活手达伤还加相未组。为此很有必要对高压电动隔离开关支柱绝缘子断裂的原因进行认真分析,查明断裂的主要原因,提出防范措施和技术改进,为高压电动隔离开关可靠运行提供保障,确保电力系统安全稳定运行。

红调余小语费失自团着厂 1支柱绝缘子的特性分析

1.1支柱绝缘子的组成

绝缘子一般由绝缘体、金属附件、胶合剂三部分组成。绝缘体主要起绝缘、支撑、保护作用。金属附件一般用铸铁低碳钢、铝及合金等组成,起机械固定、连赵均商期接作用,而胶合剂的作用是将绝缘体和金属附件胶合起来。

1.2支柱绝缘子的机械性能

绝缘子在运行过程中需要承受导线以及导体的重量、覆冰重量、设备操作过程中的机械力及交流运创烟称神美行中短路后的电动力、风块力、地震等由外界引起的负荷力。所以,其机械性能要求很高,一般要求产品在出厂时要做抗弯、抗扭试验。

1.3支柱绝缘子的原料组成

绝缘子的坯、釉料的成分主要有二氧化硅、三氧化二铝及少量的碱金属氧卷刘维增化物以及碱土金属氧化物。因此,坯料是由黏土、长石、石英以适当比例配合而成,在一般高强瓷中需要使用高铝及其他原料,而在电瓷釉料中,还需加入一些金属氧化物,以增加绝缘子强度。

1.4支柱绝缘子烧制过程中强度及硬度的变化

支柱绝缘子在烧制过程中,其硬度随着温度的逐渐增高以及烧制时间逐步增加,在小火阶段,坯体的强度略有增加,上督记又矛米在900度以后,标坯体强度会不断增加,且由于形成长石-石英玻璃及莫来石晶体,使坯体的硬度逐渐提高。

1.5支柱绝缘子的受力分析

根据支柱绝缘子机械结构及几何分布,应用有关力学原理进行分析表明,绝缘子下瓷体法兰附近受的剪应力最大,几十年来,我们接触到的以及其它地区发生的高压隔离开务关绝缘子断裂部位都在绝缘子下瓷体法兰附近,这一结果相互验证说明绝缘子断裂与受力密不可分。

2 支柱绝缘子的断裂原因详解

2.1制造质量存在问题

生产工艺的每一道工序都将影响产品的质量,产品完善、严格的检验制度是杜绝不合格产品出厂的主要手段。由于生产厂家利益驱使,生产工艺没有严格把关,对产品没有严格检验,没有严把出厂关,造成不合格产品流向用户。

2.2电动隔离开关安装调试不到位

隔离开关在安装调试时,没有严核多精格按照安装使用说明书的有关要求进行调整,以致操作时绝缘子受力较大,有卡涩、别劲感。

2.3一次导流部分的连接粮素动功基模似引线连接不规范

隔离开径仍情关在安装调试后,一次蒸入厚即措导流引线连接不规范,没有留有一定的弧度,而是直线连接,由于热胀冷缩及操作时的受力,绝缘子受垂直于轴向的水平力较大而发生断裂。

2.4传动部分机械卡涩

隔离开关由于长时间不进行检修,特别是实行状态检修以来,基本上是4年一次,加之有些隔离开关倒闸操作很少,长期的风吹日晒、雨林冰冻,造成传动部分氧化生锈引起机械卡涩,操作时绝缘子受的扭力较大而发生断裂。

2.5设备选型不当

绝缘子承受的机械负荷主要体现在接线端拉力上,没有充分考虑到设备所处环境的实际情况,导致在恶劣气候条件下支柱绝缘子弯曲强度低于运行要求,造成绝缘子的断裂。

2.6隔离开关的结构设计缺陷

隔离开关机械元件抗锈蚀能力差,运动部位润滑脂填充不充分,在进行操作时,机构钱载液等养套评传动卡涩、别劲,造成绝缘子承受异常弯矩或扭矩而断裂。

2.7自然环境因素影响

气候温差大和恶劣见毫台的气候条件,如热胀冷缩引起调整好的尺寸变化、暴风骤雨引起的共振,使支柱绝缘子异常受异意里补列较倒挥台工灯力超过其破坏负荷所致。寒冷地区的绝缘子,由于金属附件和胶装水泥的应力叠加,也会导致绝缘子断裂。

2.8绝缘子老化

绝缘子运行年限较长,有的超过二十年,在长年的运行中,逐步劳损,强度降低在受力时引起绝缘子断裂。

综上所述,隔离开关不论是产品质量问题,还是安装调试不到位、导流部分连接不规范、机械卡涩,或者是设计、选型不当,以及自然环境因素影响老化等,最终断裂都与受力有关。

New Measures to Avoid theFracture of High Voltage Post Insulator of Electric Isolating Switch

Abstract:

Thefracture of post insulator may occur during the order sheet for the electricisolating switch which operation requires continually check in the electricpower system. It can cause massive power outage regionally and can even be asevere threaten to the operators and the equipments. We made a collection ofthe accidents and analyzed the reasons from the aspects of anti-pulling force,poor quality, installation and debugging, to jam faults during transmission andmany and concluded that any kind of fractures are related to the forces that thepost insulator bear. In this sense, we propose a few new measures in the pointof electric controlled operation for the circuit.

Key words:

avoid; electric isolating switch;insulator; fracture; new measures

Foreword:

The fractureaccident occurs in the operation of the order sheet for the high voltageelectric isolating switch and arouses immeasurable consequences on the reliabilityof the power distribution device, the stability motion of the electric fenceand the supply to the users on the main lines. Not long ago, we'veunfortunately been the fracture accidents in Pingyuan, Yijing, Shengzheng, Sha'anxi,and Yanan substation at the kilovolt 110, 220, 330, 500. The aftereffect interruptedgrievously the routine lives of the users in large scale. In order to promoteand protect the high voltage post insulator of electric isolating switch andavoid the fracture, to provide a safe and stable motion, it is essential thatwe analyze these accidents and find out the reason that causes it.

1: specificityanalysis

1, 1 from of thepost insulator

The insulator is form of insulator, metal accessory and cement. Themain function of the insulator is insulation, support and protection. The metalaccessory is mainly formed of iron casting low carbon steel, aluminum andalloy. It mechanical fix and connect the parts. The cement is used to stick theinsulator and metal accessory together.

1, 2 mechanicalproperties of the post insulator

In the motion the insulator bears the weighof the wire, the conductor and the covering ice mixed with force of themechanical power during the motion, the electrodynamics and wind power afterthe short circuit in alternating motion, also load force caused by the externalword, like earthquake. Therefore the mechanical properties are highlydemanding. The insulator is exactingly tested on the flexible and torque strengthbefore leaving the factory.

1, 3 raw materialcompositions of the post insulation

Silica, aluminum oxide, a small amount of alkali metal oxide and alkali earthoxide is the component of the insulation. The billet is composed in proportionof clay, feldspar, quartz. The high tensionporcelain requires high aluminum and others. The electric porcelain needs someextra metallic oxide to strength the insulation.

1, 4 strength andhardness changes of post insulation during firing procedure

When lowheating, the adobe strength increases a little bit following the rising of temperatureand time. After passing 900 centigrade, the strength grows sharply with thehelp of feldspar-quartz glass and mullite crystal.

1, 5 force analysis of post insulation

The shear strength goes up tothe highest around the flanged porcelains according to the mechanical structure and geometric distribution of theinsulation, also with relative evidences from mechanical principles analysis. Inthe past decades years, the fracture accidents all assemble

around the flanged porcelains. That highly shows the fractures arequite possible caused by the force it bears.

2: explanation of the post insulation fracture

2, 1 poor quality

Theproducers driven by the improper benefits neglect the procedure and the qualityinspection in order to produce more. Each procedure affect the final productand that kind of poor quality account for the main responsibility for the fractureaccidents.

2, 2 incorrectly installation of the electric isolation switch

The insulation bears more forces and stucksif not installed or adjusted exactly according to the instruction.

2, 3 improper connection of the lead wire in the diversion part

The lead wire is connected in a straightinstead of remaining a certain radian, which would ends in causing fractureonce forced by thermal expansion and contraction or horizontal stress in themotion.

2, 4 mechanical jam in the transmission part

The overhaul for the isolatingswitch is neglected for long time, only goes once in four years especially afterthe condition-based maintenance is conducted. And because there is merely anorder sheet, the transmission part is oxidation of rust due to long exposure tosunlight and natural water. When operating, the insulation will beak out inresult of the torsion.

2, 5 improper selection of equipment

The mechanical loads of the insulationmainly embody in the pulling force that the terminal bears. The bending strengthof the post insulation should fit any adverse conditions that it is depositedin, otherwise it breaks.

2, 6 structure design defect of the isolation switch

The mechanical component in lowanti corrosion ability, no enough grease in the motion parts and other reasonswould all cause the torques and bending moments that commit the transmissionparts stuck and break.

2, 7 natural environment factors

Largetemperature difference and adverse climate make the abnormal strength that the insulationbears exceeding the damaging load, such as the size varies from the thermalexpansion and contraction, resonance raised by the storm, the multiplied stressby mental accessory and cementing cement would all bring the fracture.

2, 8 ageing of the insulation

The long-time running, some evenup to 20 years, of the insulation will damage the capacity that it bears the strength.And then the fracture happens.

From all above we can see whatever cause it is, the fracture is closelyrelated to the force that the insulation bears.

.

评论留言